Redundant Encoder Options

While most modern rotary encoders rely on non-contact sensing technologies and have high MTBF specifications, in critical applications it is still common to have redundant sensors required. When selecting a solution, a number of different criteria need to be considered and fortunately different solutions exist, making the task less daunting.

Redundancy

One of the first things to consider is how redundant does your sensor need to be? For example, does it need to be completely redundant, such as all of the electronics and mechanical components are duplicated? Or can it just be electronically redundant and use common mechanics, thus making installation easier and reducing costs? Zettlex’s INC-10 ‘Duplex’ InOder provides an elegant hybrid solution. Mechanically a smaller IncOder is nested within a larger IncOder, creating two fully redundant sensors which share a mechanical housing, but nothing else.

Mechanical Constraints

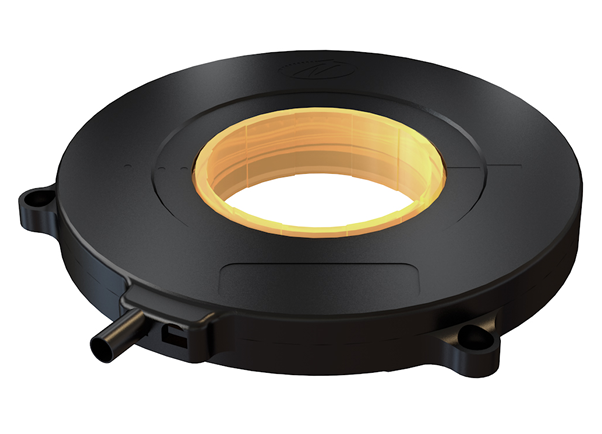

While often purchasing two standard standalone encoders is the most economic option, it often creates added installation complexity. For example, consider an end-of-shaft installation. There is only one ‘end-of-shaft’. In order to install two encoders a gear or some other mechanical modification would be necessary. In some end-of-shaft applications a through-hollow encoder can be placed over the shaft and then the traditional end-of-shaft can be used at the end. The small form factor of Netzer’s DS series rotary encoders make them ideal for pairing up with a shafted encoder.

Other Considerations

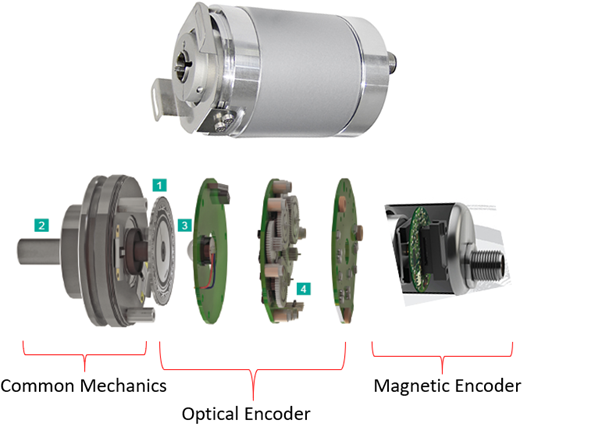

Each technology (optical, magnetic, inductive, capacitive) has its own strengths and weaknesses. In some applications a designer may incorporate two different technologies into a design to provide protection for any potential weakness. POSITAL can even combine their optical and magnetic platforms into one shafted encoder, keeping installation straightforward, yet providing full electrical redundancy.

856-727-9500

856-727-9500