POSITAL

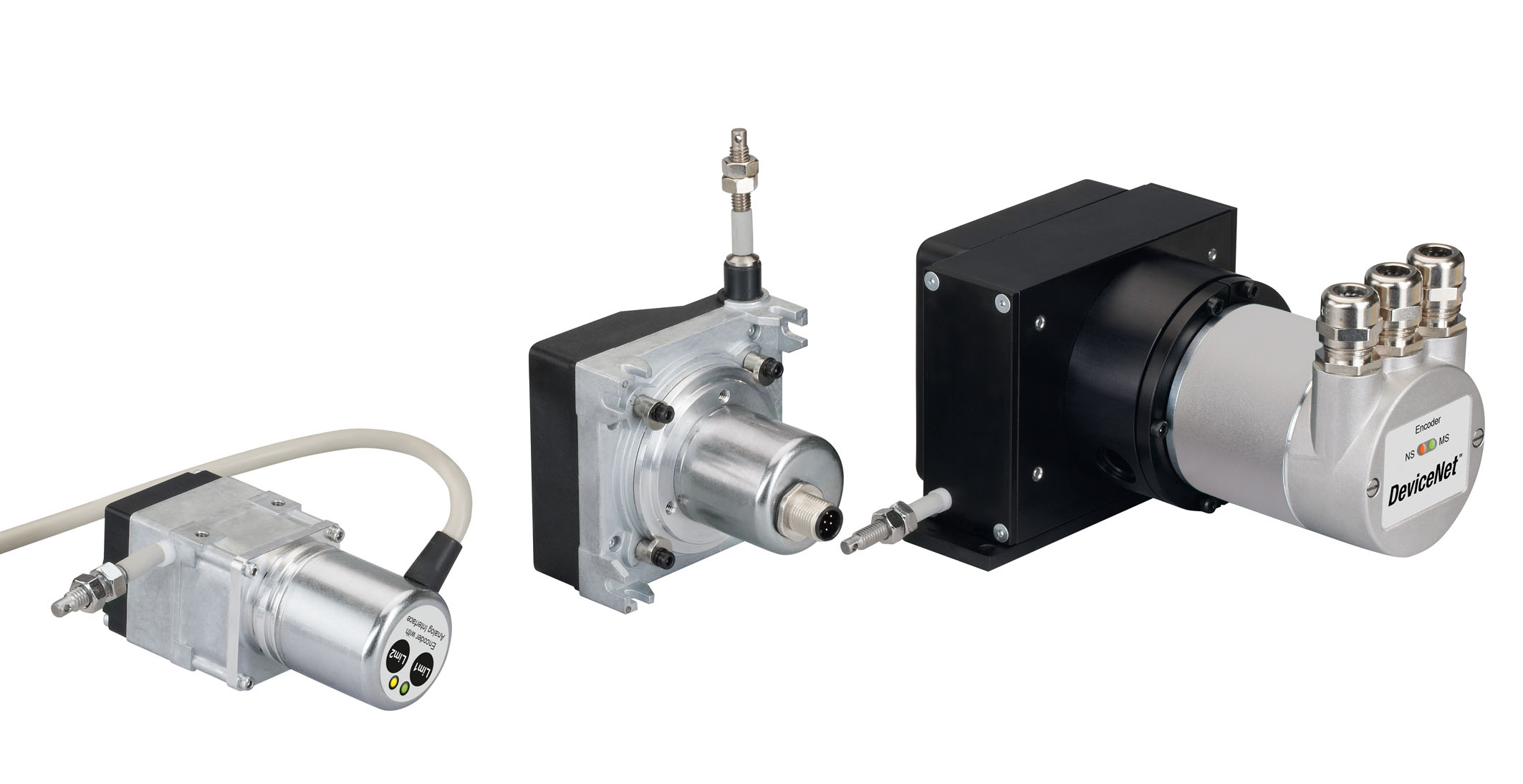

POSITAL UCD – Ethernet

Part no.: POSITAL UCD – Ethernet

Key Features

• Up to 16 bit resolution

• Support for bus-in/bus-out daisy chaining

• Optional stainless steel housings

• Dianostic LEDs for easy setup

POSITAL encoders support a number of common industrial ethernet protocols, including EtherNet/IP, PROFINET, EtherCat, MODBUS TCP/IP and Powerlink.

856-727-9500

856-727-9500