Liquid Level Sensor Interface

The GS liquid level software is an excellent resource for people using sensors to measure fuel, chemicals, or even waste. One of the best features of the Gill Liquid Level Sensors is its compatibility with the GS Level software. The GS Level software makes it easy for the end-user or integrator to change the setting […]

Spine Surgery Robot

Spinal surgery robot with advanced robotic guided technologies supports high requirements of predictable surgical procedures.

Compact, Lightweight, Inductive Ring Encoders

IncOder™ CORE is a robust miniature PCB-based inductive ring encoder designed for robotic joints. IncOder CORE is a non-contact, lightweight absolute rotary inductive encoder fully contained in a printed circuit board kit. The ergonomic hollow bore design is suited for integration into rotary actuators. The position sensor utilizes a unique field-proven inductive technique, delivering highly repeatable, […]

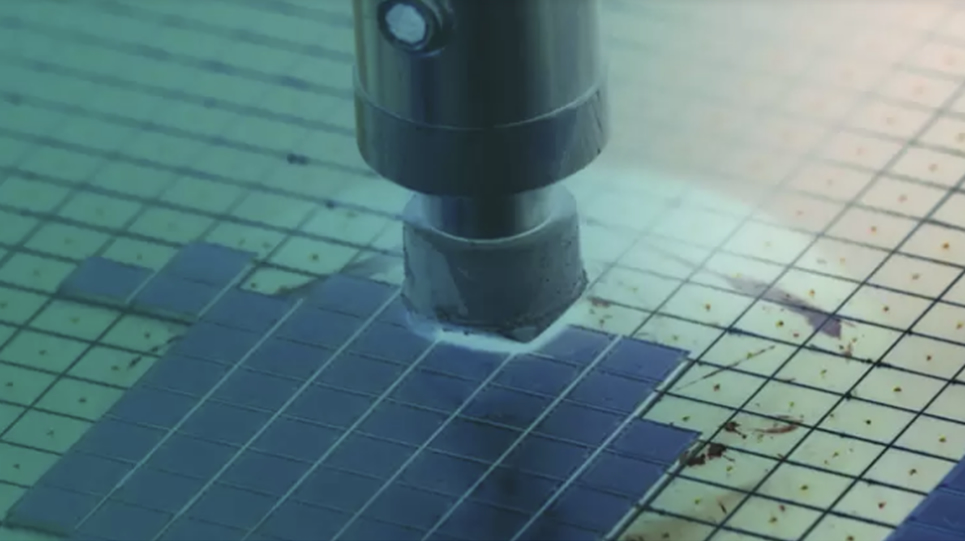

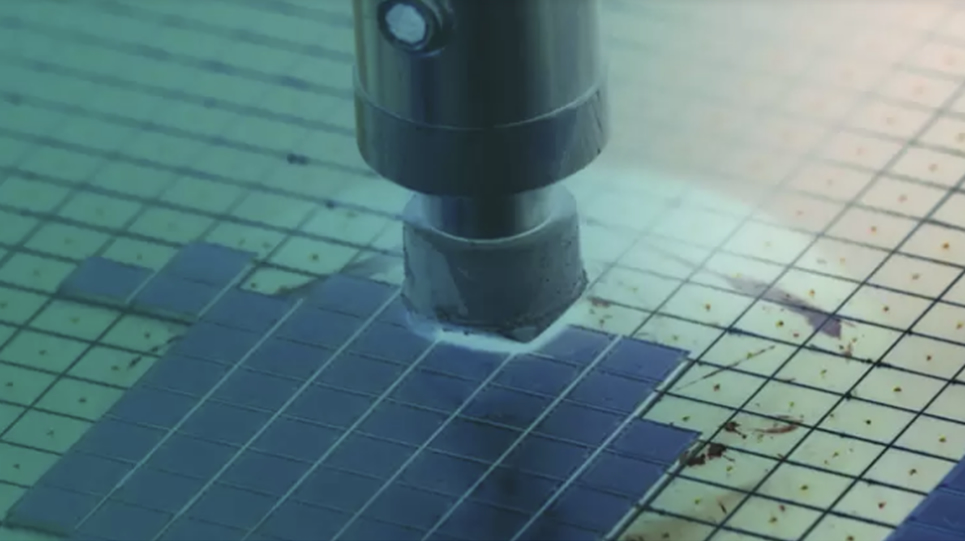

Chips, Chips & Chips

What semiconductors, snacking and gambling all have in common: Encoders!

There has been a lot of talk lately around the global ‘chip’ shortage. Even social media last month was filled with cartoons of engineers asking Santa for semiconductors for Christmas. Rotary encoders such as the DS-130 by Netzer Precision are an important part of this ‘chip’ production. Accuracies exceeding 0.004 degrees, 21 bit resolution and a 90mm ID ensure that component placement can be done accurately and consistently.

VLP Product Line For Harsh Environments

Netzer Precision Position Sensors is pleased to introduce the VLP (Very Low Profile) line of absolute position rotary encoders for harsh environments. Designed for exposure to the extreme conditions that are prevalent in the Aerospace and Harsh Environment industries, the VLP-60 and VLP-100 encoders provide unparalleled performance while offering high levels of immunity to shocks, vibration, humidity, and extreme temperatures, and […]

Redundant Encoder Options

While most modern rotary encoders rely on non-contact sensing technologies and have high MTBF specifications, in critical applications it is still common to have redundant sensors required. When selecting a solution, a number of different criteria need to be considered and fortunately different solutions exist, making the task less daunting. Redundancy One of the first […]

Torque Measurement with Angle Sensors

As collaborative robots expand into manufacturing environments the issue of safe motion continues to be a concern. Current design approaches involve adding force sensors, torque sensors, and sometimes proximity sensors. These adders along with more complex software control algorithms mitigate most of the concerns and result in slower operation. Unfortunately, these additional sensors also add significant cost and complexity.

MR330 System Series

Micronor MR330 series is the only 100% Passive Fiber Optic Absolute Position Sensor System available on the market today. The innovative design is based on an all-optical passive sensor and remote interrogator module interconnected by an industry-standard multimode fiber optic link.

Netzer Electric Encoder Explorer Software

Get started with Netzer Electric Encoder Explorer Ready to learn how to get started with Netzer Electric Encoder Explorer? We can help! Take a look at this video where we walk you through the software and teach you the ins and outs of the Netzer Electric Encoder Explorer. Start with Signal Amplitude One of the […]

TECHNOLOGY LINEAR SENSORS

Many applications require linear motion to be monitored for system control or to ensure safety. With lengths ranging from 1 m to 30m (3’ to 98’), LINARIX linear sensors are available in many configurations to meet an application’s requirements. Options include a wide variety of outputs (including analog, fieldbus and Ethernet variants), heavy duty housings and compact design.

856-727-9500

856-727-9500